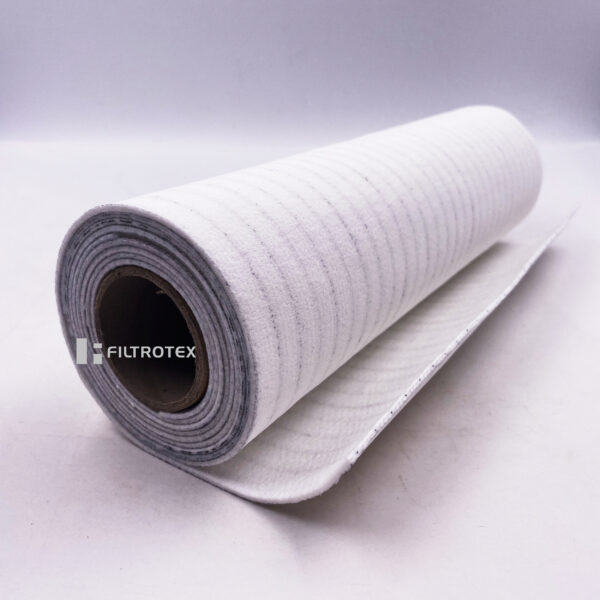

Anti-Spark Polyester Needle Felt

Especially in metallurgical processes, hot, sometimes burning particles come into contact with the needle felt. We produce anti-spark needle felt to protect the filter media from these dusts. It increases the resistance of the needle felt to flying sparks. And also offers excellent resistance to abrasion and mechanical wear.

1)Protection from flying sparks

2)Thermally resistant even at high contact temperatures

3)Extended operational life

Ask for free sample or trial order, please click here.

- Description

Description

1.Description of Anti-spark Polyester Needle Felt: (Can be customized)

Our Anti-spark Polyester Needle Felt is a new filter media with carbon coating. We use special finish treatment to extend its performance and lifetime.

2.Specifications of Anti-spark Polyester Needle Felt:

- Material : polyester staple fiber, carbon powder

2. Scrim: polyester staple yarn

3. Width: ≤2.2m

4. Thickness:1.7mm

5. Weight:400-600g/m2 ±10%

6. Brand Name: FILMEDIA

3.Features of Anti-spark Polyester Needle Felt:

- Anti-spark

2. Good anti-acid, good anti-alkali, good hydrolysis stability

3. Excellent anti-abrasion

4. High quality and economical

5. Can be customized

4.Physical Characteristics of Anti-spark Polyester Needle Felt: (Can be customized)

| Fiber | Polyester staple fiber, Carbon powder | |

| Scrim | polyester staple yarn | |

| Weight(gs m) | 500 | |

| Thickness(mm) | 1.8 | |

| Width(m) | ≤2.2 | |

| Finishtreatment | Singeing, Calendering, Heatsetting | |

| Airpermeability(L/m2.s) | 200-350 | |

| Tensile strength(N/5cm) | warp | ≥1100 |

| weft | ≥1500 | |

| Tensile elongation(%) | warp | ≤35 |

| weft | ≤60 | |

| Heat shrinkage(%) | warp | ≤1.5 |

| weft | ≤1.0 | |

| Temperature(℃/℉) | Continue | 140/284 |

| Instant | 260/500 | |

5.Chemical Characteristics of Anti-spark Polyester Needle Felt:

| Anti-acid | Middle |

| Anti-alkali | Middle |

| Anti-anbasion | Excellent |

| Hydrolysis stability | Middle |