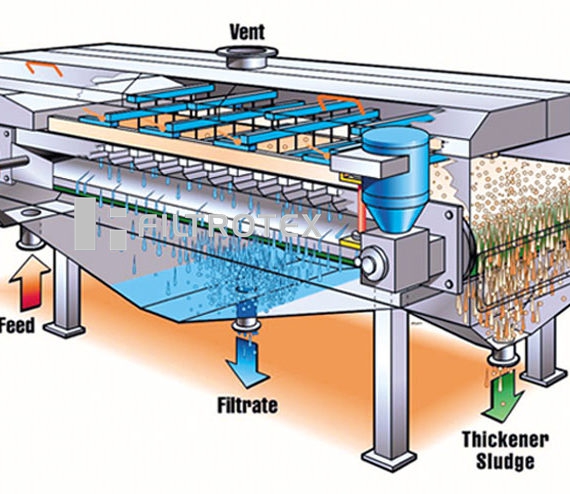

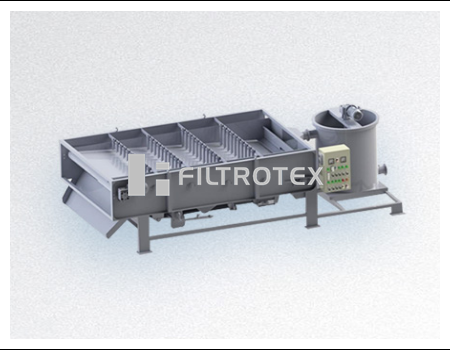

Sludge Thickener

we develp anautomatic sludge thickener which can continuously thicken the sludge steadilyin place of conventional sludge thickening pool in the long-term practice.

Sludge thickeners aredivided into two types: rotary drum sludge thickener and gravity belt sludgethickener. Haibar adopts international advanced technology and design conceptsto meet the needs of the different natures of sewage in different industries.

- Description

Description

Features

- Drum sieve with spiralblades, arranged in a certain angle. Only in this way can increase drag and time for sludge to stay on the screen, and then achieve better effect of thickening. (Drum Thickener)

- Drum sieve can adopt belt cloth because our products are sometimes related to food, such as sodiumchloride, if using stainless steel, screen will be corroded. (Drum Thickener)

- Drive bearings adoptt in bronze (graphite) self-lubrication copper sleeve, thereby reducing the operation fault of the machine. (Drum Thickener)

- Nylon oil tug service life is 10 times more than ordinary PP round and small noise when operating.(Drum Thickener)

- Bearing, belt cloth adopt international brands, to ensure the normal operation of equipment. ( Belt Filter Type Thickener)

- Requirements for PAMselection are not too strict, the amount of dosing can moderately be reduced.In the late run, costs can be well controlled. (Belt Filter Type Thickener)

Applications

Sewage treatment, chemical

Textile, printing and dyeing, paper making

Leather, pharmaceuticals, wine

Farms, etc., to replace the traditional thickener