FSF BLOWBACK BAG FILTER

- Description

Description

Overview

FSF series of blowback bag filter is a type of efficient filter with compartment cycling and blowback deashing, intake air from bottom and internal filtration, applicable to metallurgy, chemical industry, building materials, electric power, food processing, machinery and other industries, as well as civil or industrial boilers. As the equipment to purify dusty gas with dust concentration of less than 30g/Nm3, particles of more than 0.1μm and temperature of less than 280℃, FSF series has dedusting efficiency of 99% or more.

This series of products is divided into two types, i.e. FSF/G and FSF/T:

FSF/G adopts single double storehouse, single or double row square negative pressure structure, and is divided into four series according to the area of a single chamber, i.e. 83 series, 140 series, 230 series and 280 series.

FSF/T series is an assembly of a single chamber and a single storehouse, and is divided into two types, i.e. square positive-pressure type and square negative-pressure type.

In this series of filters, the selection of negative-pressure type and square negative-pressure type is based on the following principles:

Based on the dust concentration of 3g/Nm3, when the concentration is more than 3g/Nm3, the negative-pressure type is adopted; whereas, the positive-pressure type is adopted.

Based on the particle size of soot, when the particle size is larger, the negative-pressure type is adopted; whereas, the positive-pressure type is adopted. Based on the rigidity of dust particles, if soot has high rigidity and high abradability, the negative-pressure type is adopted; otherwise, the positive-pressure type is adopted.

Basic Structure

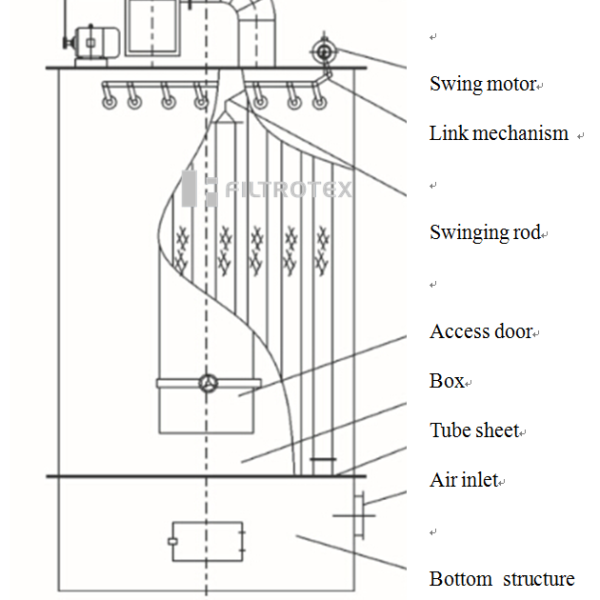

The filter is composed of a box, ash bin, pipeline, valves, ash discharging device, ladder landing and electric control system.

Box: includes the filter bag chamber, tube sheet, walking board, access door, filter bag and hanging device;

Ash bin: includes diversion board and bridging-proof device;

Pipeline: include air intake tube, exhaust duct, blowback pipe;

Valves: Tee-junction switch valve, butterfly control valve, globe valve;

Ash discharging device: The GFC is equipped with spiral ash conveyer and rotary discharge valve, and the TFC is equipped with two-stage discharge valve, ladder landing and electric control system.

Operating Principle

When dusty gas enters into the ash bin from the lower intake pipe through the diversion plate, because of resistance effect of the diversion plate and abrupt reduction of flow velocity, coarse dust particles fall, tiny dust particles enter into the chamber through the diversion pipe together with airflow. The filter bag retains dust inside, and purifies and filters gas out of the bag. The gas goes up in the box and is discharged from the outlet of Tee-junction switch valve through the exhaust duct.

After the filter runs for a period of time, dust on the filter bag is gradually thickening, and the running resistance of the filter gradually increases. When its resistance reaches a rated value, deashing mechanism will perform the compartment circulating deashing work. Under the action of airflow, after the filter bag swells up and shrinks for 2-5 times, the bag is in the stationary state, i.e. three states of deashing. When the resistance of the filter bag reduces to the lower limit of a rated value, Tee-junction switch valve restores to the filtration state. After blowback, dust falls into the ash bin, and is eliminated by ash discharging device. The whole deashing process is successively completed in each compartment, without affecting the normal operation of the filter.

The deashing mode is divided into two types, i.e. manual control and automatic control, and automatic control is divided into two types, i.e. timing control and constant resistance control.