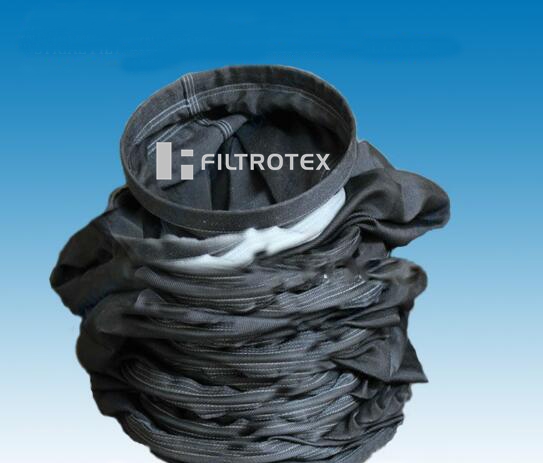

PTFE Filter Bag

As a high-grade product, PTFE filter bag has perfect filtration performance during water pre-treatment and post-treatment. Well-knowned as the updated version of PTFE, ePTFE is also available.

Monthly productivity reaches 20,000pcs, various size available, filtration accuracy precisied to better or equal 30 mg/m³.

Finish-treatment: Calendering, Heat setting, Singeing

Customization Accepted.

Optional Choice: Pleated Filter Bag (Star Bag)

The main advantages and features:

- To increase system filtration capacity by 50-150% as needed without major changes to the dust collectors ;

- System cleaning efficiency markedly increased with the effective increase of bag to bag distance;

- Bag life extended due to significant reduction of fatigue damage to the bags due to bag to cage impact.

Ask for free sample or trial order, please click here.

- Description

Description

Specification of PTFE Filter Bag:

| Heat resistance | up to 300℃ |

| Fabric | 100% PTFE fiber |

| Length & diameter | No limited |

| Area weight (g/m²) | 700~800 |

| Working lifetime | 12000 hours and more |

| MOQ | 50pcs |

Features of PTFE Filter Bag:

- Excellent temperature resistance: up to 300℃ (572℉)

2. Extremely long working life. Service life can reach 6 years at the temperature 66℃~204℃ and normal working conditions.

3. Excellent performance of anti-acid and anti-alkali resistance

4. Excellent filter efficiency

5. Good performances of hydrolysis stability and flame retardant

6. Suitable using on various power plant boiler and waste incineration boiler. The weakness is poor folding property and higher price.

Surface Treatment of PTFE Filter Bag:

There are 2 kinds of treatment : “PTFE film” and “PTFE dipping”

PTFE film: Improve filtration precision: ≤10mg/m³, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

PTFE dipping: Improve filtration precision: ≤25mg/m³, does not lower the filtration efficiency; and a small increase in acid-base resistance property

Physical properties:

| Air permeability(L/m².s) @200pa | Tensile strength(N/5 cm) | Temperature(℃ / ℉) | ||

| warp | weft | Operating | Ultimate | |

| 100~200 | 1000 | 1100 | 260 / 500 | 300 / 572 |

Chemical properties:

| Acid Resistance | Alkali Resistance | Hydrolytic Resistance | Oxidation Resistance | Abrasion resistance |

| Excellent | Excellent | Excellent | Excellent | Moderate |