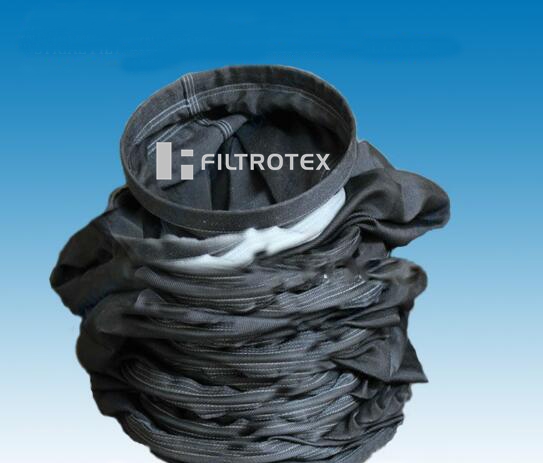

PPS(Ryton) Filter Bag

Our capacity: 20000 per month (standard product)

Diameter & Length: Accept customization

Optional process: Sewing or hot welding

Filtration precision: ≤30mg/m³ (laminating PTFE film, ≤5mg/m³)

Area weight (g/m²): 350~700

Temperature resistance: up to 200℃ (392℉)

Finish-treatment: Calendering, Heat setting, Singeing

Optional Choice: Pleated Filter Bag (Star Bag)

The main advantages and features:

- To increase system filtration capacity by 50-150% as needed without major changes to the dust collectors ;

- System cleaning efficiency markedly increased with the effective increase of bag to bag distance;

- Bag life extended due to significant reduction of fatigue damage to the bags due to bag to cage impact.

Ask for free sample or trial order, please click here.

- Description

Description

Application of PPS(Ryton) Filter Bag:

PPS often used in coal-fired boilers, but also for waste incinerator, coke oven, kiln, chemical drying process of flue gas purification process. In carbon black, powder collection, pneumatic conveying, chemical, cement plants, power plants and so on.

Notice:Common brand of PPS include Ryton® and Procon® and belong to Philip Company.

Features of PPS(Ryton) Filter Bag:

The acid and alkali resistance is Excellent. Meanwhile, PPS fiber does not burn, neither does it support burning. The temperature resistance is up to 200℃ (392℉). The resistance to oxidation is poor. So the working environment requires the oxygen content less than 14%(Vol.), and the oxynitride content is less than 600mg/Nm³. The higher oxygen contents the lower working temperature.

Physical properties:

| Air permeability(L/m2.s) @200pa | Tensile strength(N/5cm) | Temperature(℃) | ||

| warp | weft | continue | instant | |

| 150~300 | 900 | 1100 | 190 | 200 |

Chemical properties:

| Acid Resistance | Alkali Resistance | Hydrolytic Resistance | Oxidation Resistance | Abrasion resistance |

| Excellent | Excellent | Excellent | Poor | Good |