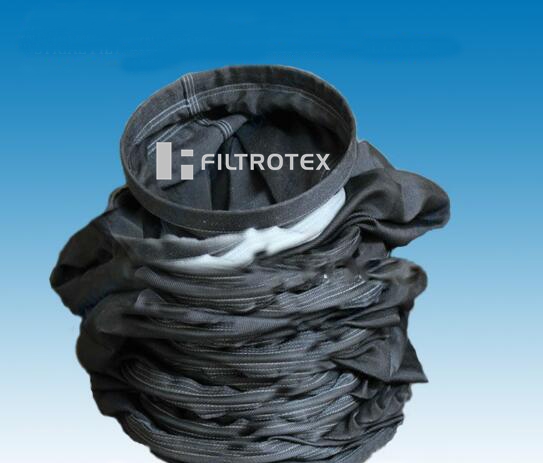

Polyester Filter Bag / PE Filter Bag

Our capacity: 20,000 per month (standard product)

Size: Customization Accepted

Optional process: Sewing or hot welding

Filtration precision: ≤30mg/m³ (laminating PTFE film, ≤5mg/m³)

Finish-treatment: Calendering, Heat setting, Singeing

The main advantages and features:

- To increase system filtration capacity by 50-150% as needed without major changes to the dust collectors ;

- System cleaning efficiency markedly increased with the effective increase of bag to bag distance;

- Bag life extended due to significant reduction of fatigue damage to the bags due to bag to cage impact.

- Description

Description

Specification of Polyester Filter Bag:

| Heat resistance℃/℉ | up to 130/266 |

| Fabric | 100% polyester |

| Length & diameter | No limited |

| Area weight (g/m2) | 350~650 |

| Working lifetime | 8000 hours and more |

| MOQ | 50pcs |

Physical properties:

| Air permeability(L/m2.s) @200pa | Tensile strength(N/5cm) | Temperature(℃/℉) | ||

| warp | weft | continue | instant | |

| 200~300 | 1300 | 1500 | 130/266 | 150/302 |

Chemical properties:

| Acid Resistance | Alkali Resistance | Hydrolytic Resistance | Oxidation Resistance | Abrasion resistance |

| Moderate | Moderate | Poor | Good | Excellent |