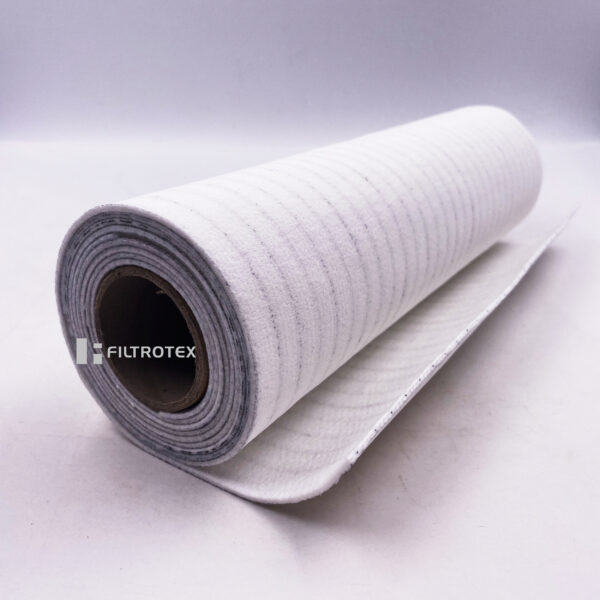

Homopolymer Acrylic Needle Felt

Our capacity:15000 square meter per day (standard Acrylic product)

Diameter & Length:Accept customization

Acrylic Needle Felt is mainly used in the detergent, waste incinerators, asphalt, dance spray dryer, coal mill and power plant, reducing environmental pollution.

Finish-treatment: Calendering, Heat setting, Singeing

Ask for free sample or trial order, please click here.

- Description

Description

Advantages of Acrylic Needle Felt:

- Excellent anti-acid and alkali: PH ranges from 3-11

2. High Filtration Efficiency: reach to 99.5%

3. Hydrolysis Stability

4. Stable working time: up to more than 3000 hours. Could be used cyclically

5. Variety of finish treatments;

| Water&Oil proof | PTFE Membrane | Anti-static |

| Acrylic Coating | PTFE Impregnation | Carbon Coating |

- Customized by order.

Specification of Homopolymer Acrylic Needle Felt:

- Material : 100% Acrylic staple fiber

2. Scrim: with Acrylic staple yarn

3. Width:≤2.2 m

4. Thickness:1.2-2.0 mm

5. Weight:300 -600 g/m2 ±10%

6. Temperature (℃): Continue: 120, Instant: 140.

Features of Homopolymer Acrylic Needle Felt:

- Excellent hydrolysis stability

2. Good anti-acid and alkali, PH ranges from 3-11

3. Relative humidity less than 30% , beware of the oxidation

4. High quality and economical

5. Can be customized.

Physical and Chemical Properties of Homopolymer Acrylic Needle Felt

| Weight(gs m) | 500 | |

| Thickness(mm) | 1.8 | |

| Width(m) | ≤2.2 | |

| Finish treatment | Singeing, Calendering, Heat setting | |

| Air permeability(L/m2.s) | 200-350 | |

| Tensile strength(N/5cm) | warp | ≥900 |

| weft | ≥1000 | |

| Tensile elongation(%) | warp | ≤35 |

| weft | ≤60 | |

| Heat shrinkage(%) | warp | ≤1.5 |

| weft | ≤1.0 | |

| Temperature(°C) | Continue | 120 |

| Instant | 140 | |

| Anti-acid | Excellent | |

| Anti-alkali | Excellent | |

| Anti-abrasion | Good | |

| hydrolysis stability | Excellent | |