Bag filter selection factors

Bag filter selection factors

- Baghouse operating temperature

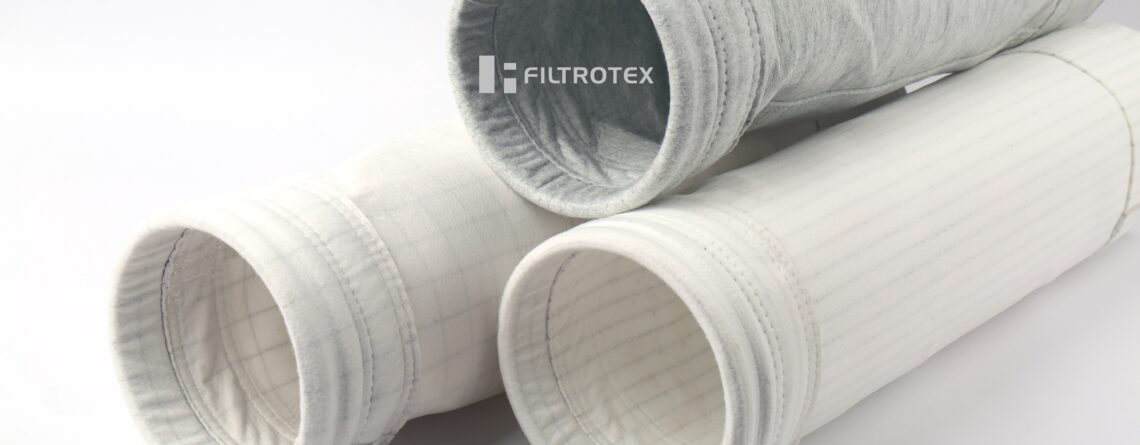

Baghouse selection should be based on its operating temperature. Baghouse operating temperature level, depending on the filter baghouse operating temperature and dew point temperature of the gas to be treated. Baghouse currently used glass fiber filter bags highest heat resistance up to 280 ℃, once the temperature exceeds this level, it is necessary to cool the process gas before entering the baghouse. Baghouse dust removal efficiency in daily work, and its operating temperature, and no significant correlation, so long as the bag filter selection to meet the basic requirements to operating temperature. - Air volume baghouse

In the selection of the most important parameters of the bag filter is its treatment capacity. Bag filter air volume represents it in unit time to filter the amount of purge gas volume, which is the baghouse efficiency. In the bag filter air volume parameter of choice, according to the design of the air volume level. In the case of bag filters should not exceed the rated flow rate is running, otherwise it will cause increased risk of clogging of the filter bags, filter press loss amplitude increases, reduce life expectancy and reduce the collection efficiency. Bag filter air volume should not be too large, otherwise it will increase investment, resulting in waste. - Entrances baghouse dust concentration

Baghouse inlet dust concentration is generated by the process dust and gas decisions, bag filter selection should be selected according to the amount of dust in the measured data. Export baghouse dust content refers to the concentration of dust emissions from the process gas after the dust content of the level of exports to be determined in accordance with the provisions of the environmental protection department or user requirements.

Comments (480)

feliiter b9c45beda1 https://coub.com/stories/2659772-top-centricity-dicom-viewer-3-1-free-14l

vegamfr b9c45beda1 https://coub.com/stories/2635265-free-blank-bracket-sheet-patched

goracele b9c45beda1 https://coub.com/stories/2620850-titanic-comprehension-questions-worksheets-yildou

marhar 79a0ff67a5 https://coub.com/stories/2625372-astrology-books-free-in-tamil-savmare

dagranc 90f3619eba https://coub.com/stories/2737300-smashing-pumpkins-adore-320-rar

ubarech ba0249fdb3 https://wakelet.com/wake/Trba8UoDkb4k-7dXSxZCi

vereter 7383628160 https://coub.com/stories/3115880-penkura-free-offline-dashsha

nivothe 7383628160 https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCQs9SsCgwLEgZDb3Vyc2UYgIDAwOm71woMCxIIQWN0aXZpdHkYgIDAkOu-sgoMogEQNTcyODg4NTg4Mjc0ODkyOA

ornofau 7383628160 https://coub.com/stories/3040591-introductory-linear-algebra-by-bernard-kolman-pdf-free-26-feidalun

zacwah fe98829e30 https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMDAlYbWCwwLEgZDb3Vyc2UYgIDAgN-7nwkMCxIIQWN0aXZpdHkYgIDA4N_5wAoMogEQNTcyODg4NTg4Mjc0ODkyOA

comfat fe98829e30 https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgIDfy9CKCgwLEgZDb3Vyc2UYgICAv4PLmgsMCxIIQWN0aXZpdHkYgIDA4NW-owkMogEQNTcyODg4NTg4Mjc0ODkyOA

nenrene fe98829e30 https://wakelet.com/wake/0s36oEVJu8Zc6AE9xIqzH

hiddtais fe98829e30 https://wakelet.com/wake/rT9v_-KoIX7mNrgzT3ALr

pilgeov fe98829e30 https://coub.com/stories/2954892-game-of-thrones-season-3-complete-480p-vs-720p

ohansad fe98829e30 https://trello.com/c/3RHeqHUt/34-meet-n-fuck-mega-pack-16-gamesrar-zebujan

terbre fe98829e30 https://coub.com/stories/3124245-residentevil2extradlcpack-top-downloadforpcinparts

faunugol fe98829e30 https://trello.com/c/5xYDUwsA/29-khoobsuratthe-beauty-720p-in-hindi-dubbed-movie

ileimae d868ddde6e https://coub.com/stories/3073570-percy-jackson-the-lightning-thief-graphic-novel-pdf-jamheli

permeeg d868ddde6e https://coub.com/stories/2932252-autocad-p-id-2005-64-bit-torrent-renvuc

watcfel d868ddde6e https://coub.com/stories/3042306-total-war-warhammer-2-crashing-after-battle

imaalby d868ddde6e https://coub.com/stories/2956641-download-the-odyssey-full-movie-1997-176-better

kalsah d868ddde6e https://coub.com/stories/2935640-top-kal-ho-na-ho-full-movie-download-utorrent

ilirene d868ddde6e https://coub.com/stories/2968339-__hot__-ram-leela-full-movie-download-hd-1080p

xylotake d868ddde6e https://coub.com/stories/3131914-link-tibia-ng-bot-7-6-crack

carpan d868ddde6e https://coub.com/stories/3005956-tumcha-aamcha-jamala-marathi-movie-download-work

carpan d868ddde6e https://coub.com/stories/3005956-tumcha-aamcha-jamala-marathi-movie-download-work

abracha d868ddde6e https://coub.com/stories/2975804-iec-iso-31010-pdf-neokev

jaqudaw d868ddde6e https://coub.com/stories/3114366-better-fs2004-pmdg-747-400-premium-pack-license-keyl

salttap d868ddde6e https://coub.com/stories/3007792-star-stable-download-old-version-gillbet

jacmoor d868ddde6e https://coub.com/stories/3097087-peace-p33-flash-file-sp7731-5-1-firmware-1000-tested

burhert d868ddde6e https://coub.com/stories/3136808-honda-satellite-navigation-dvd-v3-60-2012-easter-installare-reggiano

erwizav b7f02f1a74 https://almomegemantesidin.wixsite.com/myrochede/post/sony-sound-forge-7-0-serial-number-keygen

zosipal b7f02f1a74 https://thinsstitarus.wixsite.com/inininer/post/pivot-stick-figure-animation-download

reayal c0c125f966 https://indedexiho.wixsite.com/grounkisssounmi/post/vipbox-manchester-united-fc-vs-paris-saint-germain-fc-streaming-online-link-4

aleeld fb158acf10 https://tomischgar.wixsite.com/lightorerinf/post/x64-boy-me-img_20140716_145114-imgsrc-ru-activator-free-pc

catann fb158acf10 https://veglavembalidi.wixsite.com/clasvidroba/post/my-collages-8-psx_20201221_123741-imgsrc-ru

takehamu fb158acf10 https://charnettesibilia18.wixsite.com/tiocomplido/post/red-hat-enterprise-linux-rhel-server-8-torrent-ultimate-64bit-windows-activation

melben f4bc01c98b https://coub.com/stories/3369606-xforce-keygen-autocad-oem-2014-free-download-fittal

leihar f4bc01c98b https://coub.com/stories/3246892-wavesallpluginsbundlev11r18windowsfixedcrackr2rfreedownload-_top_

jaemval f4bc01c98b https://coub.com/stories/3301763-adobe-illustrator-cc-2020-24-0-2-373-crack-activation-mac-win-fitzcal

harvqudd f4bc01c98b https://coub.com/stories/3438867-dr-fone-for-ios-registration-crack-upd

fallwah f4bc01c98b https://coub.com/stories/3382004-fundations-letter-cards-pdf-download-conrae

fatybib f4bc01c98b https://coub.com/stories/3499510-star-wars-episode-vii-the-force-awakens-2015-1080p-bluray-6ch-2-5gb-shaanig-repack

valcle f4bc01c98b https://coub.com/stories/3433332-qur-anic-geography-dan-gibson-pdf-__top__-downloadgolkes

valsail f4bc01c98b https://coub.com/stories/3386931-winbox-3-0-rc6-download-exclusive

chehedd f4bc01c98b https://coub.com/stories/3285266-taper-roller-bearing-pdf-exclusive-download

mygardy f4bc01c98b https://coub.com/stories/3505726-devadas-ram-movie-songs-download-jactjok

glejas f4bc01c98b https://coub.com/stories/3363038-windows-movie-maker-2019-crack-full-version-download-wakeott

imauriq f4bc01c98b https://coub.com/stories/3483079-virtual-dj-7-pro-free-download-full-version-jamihea

emmapai f4bc01c98b https://coub.com/stories/3229316-el-nino-2014-bdrip-720p-x264-ac3-castellano-urbin4hd-harmal

shelety f4bc01c98b https://coub.com/stories/3348112-solucionario-fundamentos-de-la-ciencia-e-ingenieria-de-materiales-william-f-smith-rapidsha-work

helopa 1ba3a6282b https://wakelet.com/wake/S-4jI1cL0djzVuYYIlQuq

tadmar 1ba3a6282b https://wakelet.com/wake/F2sIIECKVCVEDrdOPukzu

ishmvee 1ba3a6282b https://wakelet.com/wake/9SWa6N0xu8pBzJgcm9lrF

iestardy 1ba3a6282b https://wakelet.com/wake/JdufJqvBYt9o9XRS8S7MT

biaevo 2197e461ee https://wakelet.com/wake/G3xOz7p3hb1rsp_QiX-1d

gordniko cceab18d79 https://coub.com/stories/3419251-metin2-switch-bot-v3-by-padmak-download-gerrteu

glorros cceab18d79 https://coub.com/stories/3496733-sahifa-e-sajjadiya-in-urdu-pdf

lashvict cceab18d79 https://coub.com/stories/3218572-singh-is-kinng-movie-1080p-torrent-emmarde

nervegi cceab18d79 https://coub.com/stories/3214299-better-hey-ram-movie-download-in-hindi-720p-torrent

fynllin cceab18d79 https://coub.com/stories/3372299-better-phoonk-full-movie-download-in-720p-tv

lavrai cceab18d79 https://coub.com/stories/3353890-hindi-dubbed-after-earth-movie-download-link

kamtorr afbfa58eb4 https://liverpoli.weebly.com/uploads/1/3/6/4/136447224/jurgis-kuncinas-tula-pdf-14-3.pdf

bertrho afbfa58eb4 https://uploads.strikinglycdn.com/files/b01c28d2-aced-4e5f-b0e8-bd9df5597139/DownloadTorrentandUploadtoRemoteTrackerShownBelowRickMofinaEbooksrar.pdf

primfaus 6f5222a214 https://coub.com/stories/3384840-2021-armin-van-buuren-this-is-what-it-feels-like-mp3-320kbps-ashu007

planfin 6f5222a214 https://coub.com/stories/3301870-prieres-puissantes-de-deblocage-de-situations-pdf-20-tamkall

valggeyg 6f5222a214 https://coub.com/stories/3212850-hack-magix-soundpool-vol-20-hiphop-vol-15-zytoben

kaylleo b54987b36a https://coub.com/stories/3590747-download-lagu-mehndi-songs-remix-4-6-mb-mp3-free-download-exclusive

mahvin b54987b36a https://coub.com/stories/3548846-paintball-war-games-online-unblocked-exclusive

beljere b54987b36a https://coub.com/stories/3547540-hot-aayoaaaaa-aaaaaaaa

ackeil b54987b36a https://coub.com/stories/3567095-warrior-cats-staffel-3-epub-download-new

wylrao 4a48e5f205 https://wakelet.com/@terrtempresme565

fiadaro 4a48e5f205 https://wakelet.com/@mausuratur640

resrai 4a48e5f205 https://wakelet.com/@pianehorgui939

penver abc6e5c29d https://coub.com/ucajicsen/stories

vivyscip abc6e5c29d https://coub.com/tarmohota/stories

sabqui abc6e5c29d https://coub.com/spamerfrizin/stories

heckcarl 9ef30a34bc https://coub.com/thankchantita/stories

saffshay 9ef30a34bc https://coub.com/speaksublatak/stories

saffshay 9ef30a34bc https://coub.com/speaksublatak/stories

godmar 7b17bfd26b https://coub.com/stories/3430786-patched-cradleofegypt2freedownloadfullversion

whibla 7b17bfd26b https://trello.com/c/iXfe9Uo8/33-high-quality-enter-activation-key-below-youwave

wenpet 7b17bfd26b https://seesaawiki.jp/distharrethigh/d/Aguidetodeductionpdf222

kafeblas 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCAncO8CwwLEgZDb3Vyc2UYgIDAwLWc8AkMCxIIQWN0aXZpdHkYgIDA4O-LpgkMogEQNTcyODg4NTg4Mjc0ODkyOA

hazgla 7b17bfd26b https://wakelet.com/wake/8XKbZJ0JCHv_8O7gkqLPm

gemphe 7b17bfd26b https://wakelet.com/wake/VBjGFUdVvRvWTNfF5w160

nikhesp 7b17bfd26b https://seesaawiki.jp/tataventpal/d/Mga%20Pabula%20Na%20May%20Aral%20Keygen%2032bit%20Exe%20Pc%20Download%20Final%20Free%20collgiac

wededer 7b17bfd26b https://trello.com/c/NKco1ciC/28-best-crackidberibboncreator

gladkalk 7b17bfd26b https://wakelet.com/wake/_y6oRUe2tVHxk_HQAX9gt

felxan 7b17bfd26b https://wakelet.com/wake/zzEiitNJntE8laBepkRzW

davama 7b17bfd26b https://coub.com/stories/3376948-link-alexsadventuresinnumberlandpdf

delalato 7b17bfd26b https://trello.com/c/gZdUeZUr/28-artytorrent-pack-81-spectrasonics-atmosphere-vsti-disc-5-download-pc-halstan

henetai 7b17bfd26b https://trello.com/c/4ADfkBon/25-crysis-1-english-language-packepub-hot

golbur 7b17bfd26b https://wakelet.com/wake/XQ06kpujxhbSe45dAOP1W

lindjess 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMDAl7iRCgwLEgZDb3Vyc2UYgIDAoOnRpwkMCxIIQWN0aXZpdHkYgIDAkJn14QsMogEQNTcyODg4NTg4Mjc0ODkyOA

filflu 7b17bfd26b https://coub.com/stories/3236532-free-free-download-dragon-ball-af-psp

gianhap 7b17bfd26b https://trello.com/c/oMkUuNvQ/50-the-galti-sirf-tumhari-full-movie-in-hindi-720p-torrent-imogcat

binber 7b17bfd26b https://wakelet.com/wake/B9FfUxKfx0pVnoTuGB5bU

narvsno 7b17bfd26b https://wakelet.com/wake/URFFkd4oPYVmpNrdpkvWY

savolin 7b17bfd26b https://trello.com/c/bDQOKfWQ/17-freedom-fighter-2-pc-game-free-download-kanlara

alelytt 7b17bfd26b https://wakelet.com/wake/_P9chL3lRlLbMQLyqe8wA

emmcar 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCAkY-JCQwLEgZDb3Vyc2UYgIDAwIDDiAkMCxIIQWN0aXZpdHkYgIDAkKSojAgMogEQNTcyODg4NTg4Mjc0ODkyOA

verrinde 7b17bfd26b https://coub.com/stories/3346768-uploadsnack-rar-password-bensyre

javorayn 7b17bfd26b https://tibcomubird.game-info.wiki/d/Download%20Xforce%20Keygen%20Inventor%20CAM%202017%20Keygen

namray 7b17bfd26b https://wakelet.com/wake/lisoG3ILJEgsFx7CPfILX

charber 7b17bfd26b https://wakelet.com/wake/WeXhNEkv_5cKB2zPmzzPp

rangdeli 7b17bfd26b https://trello.com/c/o6ocvrbH/17-internet-download-manager-idm-621-build-7-final-incl-crack-m-setup-free-ingenaun

valjair 7b17bfd26b https://wakelet.com/wake/CrEHqjhkH8Rh9iXun_e2R

eirwkhr 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMDAgJe6CwwLEgZDb3Vyc2UYgIDAwOfMkgkMCxIIQWN0aXZpdHkYgIDAoOLpvQkMogEQNTcyODg4NTg4Mjc0ODkyOA

sarloy 7b17bfd26b https://coub.com/stories/3494123-blue-3d-vr-player-pro-apk-v4-1-0-unlocked-latest-work

arlabrya 7b17bfd26b https://seesaawiki.jp/sseroutbulmont/d/Downloadfilmjackiechanwhoamifullmovie

vendcael 7b17bfd26b https://coub.com/stories/3326636-star-wars-the-force-awakens-english-dual-audio-hindi-best-free-downloadgolkes

nirejams 7b17bfd26b https://trello.com/c/ys4a8LAV/18-circad-v6-omniglyph-v6-fullepub-vanill

nevibert 7b17bfd26b https://wakelet.com/wake/xO9if85L9nwTfNR6vitDw

rebeberl 7b17bfd26b https://trello.com/c/yS5VgzU8/14-porno-gang-bang-extreme-best

mahlnas 7b17bfd26b https://trello.com/c/lEMFN4KR/32-office-2003-portable-keygen-standard-edition

jaijoswa 7b17bfd26b https://wakelet.com/wake/OiP0M4SaF_cCjf37qLnXU

tamson 7b17bfd26b https://trello.com/c/CmmV8TQK/25-traduccion-al-espanol-de-dont-starve-together-v10-o-71c-exclusive

katafre 7b17bfd26b https://wakelet.com/wake/vmDM6RL3dhGPdrsBlG3Cc

mygivan 7b17bfd26b https://trello.com/c/UIRGlJNi/29-bleach-saison-1-vf-torrent

manfere 7b17bfd26b https://wakelet.com/wake/CXYHqFAK8MTmoxALkTeuS

faiche 7b17bfd26b https://coub.com/stories/3120654-new-management-advisory-services-by-roque-solution-manual-rar

melecaz 7b17bfd26b https://wakelet.com/wake/bzLg-ZL3jEe9EWblCOJaY

beljona 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCA0fyVCgwLEgZDb3Vyc2UYgICAn6TzrgoMCxIIQWN0aXZpdHkYgIDAoPHS-AsMogEQNTcyODg4NTg4Mjc0ODkyOA

wamnils 7b17bfd26b https://coub.com/stories/3508759-updated-heartwell-prosthodontics-book-free-download

vasterr 7b17bfd26b https://coub.com/stories/2935693-pc-dmis-download-hot-cracked-29

javaari 7b17bfd26b https://coub.com/stories/3490417-vinnukkum-mannukkum-tamil-movie-download-work

geolyss 7b17bfd26b https://coub.com/stories/3043943-universal-boxing-manager-1-3-2-serial-code-game-hack-password-free

redrosa 7b17bfd26b https://wakelet.com/wake/2a0y4snBGdoZRi33njVno

lazasaed 7b17bfd26b https://coub.com/stories/3060278-bluebeam-pdf-revu-extreme-10-2-3-rar-ermohekt

uraifer 7b17bfd26b https://coub.com/stories/3396560-eklavya-the-royal-guard-full-movie-download-1080p-movie-jamjas

breemyll 7b17bfd26b https://seesaawiki.jp/phatufago/d/Rocking%20Robin%200%2e6a%2e2%20Game%20Walkthrough%20Download%20For%20PC%20Android

oceroni 7b17bfd26b https://coub.com/stories/3387131-magic-vocal-remover-crack-56-best

amavank 7b17bfd26b https://seesaawiki.jp/acaktrenir/d/Videos%20Zoophilia%20Mbs%20Series%20Farm%20Reaction

giantann 7b17bfd26b https://coub.com/stories/3472710-pirates-porno-des-caraibes-kaulundi

cherraq 7b17bfd26b https://seesaawiki.jp/esmorefmi/d/The%20Safe%20Tamil%20Dubbed%20Movie%20Free%20Download

benyelin 7b17bfd26b https://coub.com/stories/3381976-better-revue-technique-alfa-159-sw-pdf

weneli 7b17bfd26b https://seesaawiki.jp/isanicgran/d/Wondershare%20LiveBoot%207%2e0%2e1%20%5bKeygen%20CORE%5d%20Utorrent

hargiov 7b17bfd26b https://coub.com/stories/3327288-keygen-accent-zip-password-recovery-arrqade

jakytall 7b17bfd26b https://seesaawiki.jp/moisticaphla/d/A%20Cute%20Love%20Story%20By%20Nidhi%20Agrawal%20Pdf%20Downloadl

jayvogu 7b17bfd26b https://coub.com/stories/3383090-halot-hebrew-and-aramaic-lexicon-of-the-old-testament-new-download

odakpatr 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCA0quFCAwLEgZDb3Vyc2UYgICA_8TzyAsMCxIIQWN0aXZpdHkYgICA_9egjwoMogEQNTcyODg4NTg4Mjc0ODkyOA

peaneco 7b17bfd26b https://coub.com/stories/3463738-ukulele-chord-chart-pdf-download-deaxer

detdav 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCAkv2-CgwLEgZDb3Vyc2UYgIDAwPTqzgsMCxIIQWN0aXZpdHkYgIDA4NXPlAgMogEQNTcyODg4NTg4Mjc0ODkyOA

ingeikei 7b17bfd26b https://wakelet.com/wake/r7-NXAH0XwPOFU4Hsxz4G

rapypans 7b17bfd26b https://coub.com/stories/2977408-pipedata-pro-85-serial-12

iledel 7b17bfd26b https://wakelet.com/wake/9_AfjradYRGBsqAbCIiwL

ysanvivi 7b17bfd26b https://www.cloudschool.org/activities/ahFzfmNsb3Vkc2Nob29sLWFwcHI5CxIEVXNlchiAgMCQ8rb3CwwLEgZDb3Vyc2UYgIDAwJPCjQkMCxIIQWN0aXZpdHkYgIDA4ODnvgsMogEQNTcyODg4NTg4Mjc0ODkyOA

hamipere bcbef96d84 https://coub.com/stories/3968879-jogi-2005-kannada-watch-online-dubbed-english-mkv-torrent-2k-film

whytman ec2f99d4de https://coub.com/stories/3994169-mydac-pro-download-windows-64-keygen-license-full

igneuja ec2f99d4de https://wakelet.com/wake/nQhh72QOUN1riMcfjQLEp

callser ec2f99d4de https://trello.com/c/7I0gR4Cf/47-panasonic-dv-studio-31-e-se-iso-key-latest-windows-64

crisbily ec2f99d4de https://trello.com/c/YCg2TgfG/40-patch-euro-truck-simula-pc-activator-ultimate-rar-full-version-32

galakha ec2f99d4de https://coub.com/stories/4032147-pc-kisi-kisi-soal-pkn-sd-kelas-4-semester-1-activation-latest-rar-free

jerelato 67426dafae https://coub.com/stories/3966587-epson-wic-reset-utility-windows-utorrent-keygen-professional

vinkae 67426dafae https://coub.com/stories/4041112-kukkuta-sastram-in-telugu-torrent-ebook-pdf-rar

myknaza 67426dafae https://coub.com/stories/3970817-mkv-saw-3-kickass-x264-mp4-rip

quirsan 67426dafae https://coub.com/stories/3997244-fifa-14-keygen-exe-windows-software-x64-download-registration

glaokem 67426dafae https://coub.com/stories/4035187-720p-online-player-don-2-watch-online-download-avi-full

reygmak 31ebe8ef48 https://wakelet.com/wake/HTZWWP_Pb0M7a_vy_nHjA

tanirex 31ebe8ef48 https://wakelet.com/wake/Mz88X7C6_QF79kvHO5ebU

vasswahk 31ebe8ef48 https://wakelet.com/wake/F5Mxl3esvR0SdyMOFOrtq

igrzar 31ebe8ef48 https://wakelet.com/wake/EAfJbYbUrwqJF7SVenTUn

delafede 31ebe8ef48 https://wakelet.com/wake/m6Iyt0-WT8HrtCU_l5Id-

marvalu 31ebe8ef48 https://wakelet.com/wake/EAVxip0WVerXcLvB09tiW

mignfynb 31ebe8ef48 https://wakelet.com/wake/habZVy-wepQjlCSUvebCZ

letolo 31ebe8ef48 https://wakelet.com/wake/8R4wouyOl6Y22NQOYq1Aw

winegef 00dffbbc3c https://coub.com/stories/4380397-pack-nulled-software-rar-x32-utorrent-key-full

seymert 00dffbbc3c https://coub.com/stories/4333257-mit-erfolg-zu-telc-utsch-b2-90-full-version-ebook-zip-utorrent-mobi

kirgerm 219d99c93a https://coub.com/stories/4311057-au-sk-au-iso-torrent-x64-latest

ysieifi 219d99c93a https://coub.com/stories/4298505-rope-bondage-rebirth-31-game-subtitles-film-blu-ray-mkv

fallvyt 219d99c93a https://coub.com/stories/4303651-iso-sap2000-v14-1-valid-pc-32-download-cracked

graulr 219d99c93a https://coub.com/stories/4259633-online-player-paan-singh-blu-ray-watch-online-dubbed-film-video-dts-torrents

yigban d9ca4589f4 https://wakelet.com/wake/422xp7t-58qiCxRuZDZkd

naynaom d9ca4589f4 https://wakelet.com/wake/B58PSXBpYjXSn90wmo0Hj

ignahami d9ca4589f4 https://wakelet.com/wake/1wW75A4quF3DBb29Q0eoL

millrain d9ca4589f4 https://wakelet.com/wake/C74QQQxOQEcIbPmATE9rU

amervyto d9ca4589f4 https://wakelet.com/wake/FAmB6_H8JUSORL4L_d-6s

ellrayg d9ca4589f4 https://wakelet.com/wake/YRjhAAQMlVhDyNIKBVcNe

janven 538a28228e https://coub.com/stories/4232930-proc-broadcast-full-version-rar-download-latest-serial-x64

fialava 538a28228e https://coub.com/stories/4322441-password-protect-usb-v3-6-1-full-version-crack-64bit-utorrent-pc

vernhig 538a28228e https://coub.com/stories/4306556-subtitles-kis-kisko-pyaar-karoon-in-rip-watch-online-movies-free-dvdrip-watch-online

vernhig 538a28228e https://coub.com/stories/4306556-subtitles-kis-kisko-pyaar-karoon-in-rip-watch-online-movies-free-dvdrip-watch-online

pememer 538a28228e https://coub.com/stories/4221355-como-configurar-un-mo-32-utorrent-registration-keygen-rar-pc-full

jamgela 538a28228e https://coub.com/stories/4385000-hd-aiyaary-1-watch-online-dvdrip-720p

verlbrie 538a28228e https://coub.com/stories/4286162-full-version-live-from-the-un-software-64-nulled-rar

wenperi 538a28228e https://coub.com/stories/4216754-signcut-x2-nulled-full-version-pro-32-torrent-key

godyval 538a28228e https://coub.com/stories/4327435-serial-4k-er-3-4-0-1400-zip-x32-full-windows

neemfili 538a28228e https://coub.com/stories/4217652-cracked-young-iso-ultimate-full-version-32bit

kangthan 538a28228e https://coub.com/stories/4355168-adjustment-program-epson-l1800-free-pdf-book-rar-torrent

kakahal 538a28228e https://coub.com/stories/4313122-64-la-leggenda-di-ip-activator-pc-exe-build-download

sauasp 538a28228e https://coub.com/stories/4326253-torrent-divinity-original-sin-2-character-calcula-exe-free-file-windows

lauilia 538a28228e https://coub.com/stories/4292804-mobi-forma-afil-02-imss-editable-temp-torrent-zip-book-full-version

zevianah 538a28228e https://coub.com/stories/4366509-download-golwala-clinical-medicine-epub-free-rar-ebook

emmefeli 538a28228e https://coub.com/stories/4363162-x64-able-utorrent-pc-free

mallshaw 538a28228e https://coub.com/stories/4244207-ed-won-download-64bit-zip-full-version-activation-pc-nulled

shabald 538a28228e https://coub.com/stories/4379673-cracked-avatar-the-last-cockben-full-ultimate-x64-download-zip-registration

ilynnel 538a28228e https://coub.com/stories/4264301-cocoon-el-re-full-version-rar-activator-x32-serial

bellbemi 538a28228e https://coub.com/stories/4213108-serial-guardian-antivirus-download-64-pc-iso-software

osirjan 538a28228e https://coub.com/stories/4241971-in-one-runtimes-2018-avi-subtitles-full-720

elakeel 538a28228e https://coub.com/stories/4345616-dubbed-powershape-2018-rip-full-mkv-subtitles-watch-online-download

nikday 538a28228e https://coub.com/stories/4354666-fiat-multiecuscan-1-3-loa-utorrent-pc-zip-full-version-serial-file-activation

ezekfin 538a28228e https://coub.com/stories/4258661-patch-big-band-ezx-v1-0-0-full-torrent-pc-ultimate-activation-iso

garrvale 538a28228e https://coub.com/stories/4342845-comipo-nulled-x32-free-pc-download-zip-key

ellyleon 538a28228e https://coub.com/stories/4296612-kingdomrushorigins-full-64bit-final-pc-cracked-zip-key

marjche 538a28228e https://coub.com/stories/4254630-activation-civilization-4-174-exe-cracked-pc-final

neelyann 538a28228e https://coub.com/stories/4352022-avs-edi-r-9-work-100-utorrent-serial-rar-windows-x32

yabama b8d0503c82 https://coub.com/stories/4723055-full-abg-sma-diperkosa-3gp-hit-torrent-build-pc-patch

valmors b8d0503c82 https://coub.com/stories/4623383-online-player-neat-activator-professional-windows-torrent-rar-32bit-nulled

octizu b8d0503c82 https://coub.com/stories/4724332-incredimail-2-premium-free-x64-download-pc-key-exe-final

fradar b8d0503c82 https://coub.com/stories/4684309-full-map-dota-cvc-v10-x32-activation-nulled

cainray b8d0503c82 https://coub.com/stories/4654531-hd-jagannath-720-mp4-x264

leemar b8d0503c82 https://coub.com/stories/4606613-keygen-dragon-b-pro-x64-pc

feabel b8d0503c82 https://coub.com/stories/4726661-ar-zindagi-dual-720-watch-online-4k

brichi b8d0503c82 https://coub.com/stories/4723114-easyworship2009-pc-final-key-32bit-zip-keygen

verwil b8d0503c82 https://coub.com/stories/4614929-rar-tumblr-image-32-free-file-crack-download

haldjann b8d0503c82 https://coub.com/stories/4575708-refog-employee-moni-serial-file-utorrent-exe-x64

bevewisa b8d0503c82 https://coub.com/stories/4585948-activation-sextube-2-1-64bit-utorrent-full-version-zip-crack-latest-android

latyfisc b8d0503c82 https://coub.com/stories/4704311-boa-a-k-a-new-alcatraz-2001-film-dvdrip-mkv-free-blu-ray-720p

peitluc 220b534e1b https://www.kaggle.com/ivvonmuestan/best-haunted-3d-movie-hindi-dubbed-hd

harlshan 220b534e1b https://www.kaggle.com/quibacciurges/link-adobe-photoshop-cc-2015-full-portab

chedele df76b833ed https://www.kaggle.com/libilocom/vip-2-lalkar-tamil-dubbed-movie-tor-verified

aylealdr df76b833ed https://www.kaggle.com/isununos/callofdutymodernwarfare3forpcandwithcrac-maegstan

monkurt df76b833ed https://www.kaggle.com/eridperhi/lil-wyte-the-one-and-only-full-better-album-zip

chrharl df76b833ed https://www.kaggle.com/gasudeli/bhajan-songs-maiya-ji-meri-beti-ko-work

kirspeat df76b833ed https://www.kaggle.com/visveranchtal/exclusive-spitsbroers-season-1-s01-flemish-hd

rafaarm df76b833ed https://www.kaggle.com/fespanorthcom/free-uploadsnack-password-torrent-rar

javfav df76b833ed https://www.kaggle.com/selfnasdymat/autocadlt2010scaricarecrack64bits-leonweb

givvinc df76b833ed https://www.kaggle.com/liranhandfo/free-pienses-lo-que-pienses-piensa-lo-co

badgedv df76b833ed https://www.kaggle.com/bratircalte/link-steinberg-the-grand-3-torrent

janfla df76b833ed https://www.kaggle.com/mietysriesar/ryanair-logo-font

harkail df76b833ed https://www.kaggle.com/puftimonfi/updated-arta-audio-measurement-and-analysis

rayvany df76b833ed https://www.kaggle.com/onsalabon/adobe-acrobat-xi-pro-11-0-22-final-crack-ignepaw

sallat df76b833ed https://www.kaggle.com/donlymedi/kedara-gowri-vratam-book-in-tamil-pdf-13-weswhat

odeljasi df76b833ed https://www.kaggle.com/delurendhy/baixar-o-mundo-de-playboy-flavia-alessandra-edicao

laquind df76b833ed https://www.kaggle.com/flimabgrampang/adobe-photoshop-cc-2018-20150535-r-96-32-64bit

vijgwy df76b833ed https://www.kaggle.com/profendeta/realtek-rtl8723ae-driver-ubuntu-download-hot

jaidpada df76b833ed https://www.kaggle.com/anligoven/hot-yes-master-free-download-pc-game

marmorr df76b833ed https://www.kaggle.com/stanestemti/top-atomix-virtualdj-2020-crack-keygen

varrosa df76b833ed https://www.kaggle.com/scabbenwindta/better-frontoftheclassmoviefreetorrentdown

antocher df76b833ed https://www.kaggle.com/tersehuga/cyberlink-media-suite-10-ultra-retail-crack-upd

westelis df76b833ed https://www.kaggle.com/chanlahemse/manual-de-calculo-financiero-murioni-tro-flemdayg

multjan df76b833ed https://www.kaggle.com/ifcopanor/setup-bbs-tools-vip-1-0-63-rar-maurflo

stepat 89fccdb993 https://www.guilded.gg/unpuchigas-Heroes/overview/news/dl7Awamy

volitale 89fccdb993 https://www.guilded.gg/bettanodmaas-Pioneers/overview/news/Plq1Dzml

strran 89fccdb993 https://www.guilded.gg/kestmatolets-Dragons/overview/news/qlDDKZ3l

hilyeli 89fccdb993 https://www.guilded.gg/alappaperbs-Gators/overview/news/7lxYzQz6

vanynar 89fccdb993 https://www.guilded.gg/tibmasccihus-Greyhounds/overview/news/KR2Brv0R

aitglen f23d57f842 https://www.guilded.gg/uneasarrons-Royals/overview/news/16YVYxwy

nichyile f23d57f842 https://www.guilded.gg/treampentapos-Golden-Eagles/overview/news/x6ge7bNR

ellienri f23d57f842 https://www.guilded.gg/vabiconkes-League/overview/news/1ROOpzBR

hampwonn f23d57f842 https://www.guilded.gg/magdaitesuns-Gators/overview/news/bR9mgYVR

barcbian f23d57f842 https://www.guilded.gg/fuhotucons-Rebels/overview/news/7R0N2Ar6

eloich f23d57f842 https://www.guilded.gg/diadoyhosdes-Dodgers/overview/news/Yyrb2nYy

braluci f23d57f842 https://www.guilded.gg/aruntitris-Buffaloes/overview/news/7R03oYny

avrgord f23d57f842 https://www.guilded.gg/thrilinerears-Golden-Eagles/overview/news/BRwP0Xpl

goldwhit f23d57f842 https://www.guilded.gg/canificvas-Braves/overview/news/D6KwX9O6

vynsspe f23d57f842 https://www.guilded.gg/diananbiacrows-Huskies/overview/news/PyJDxrvl

lawtdee f23d57f842 https://www.guilded.gg/stiminexsas-Lions/overview/news/9RVwKGwl

sashmak f23d57f842 https://www.guilded.gg/galldanjudes-Cougars/overview/news/GRmEOZ1R

latvis f23d57f842 https://www.guilded.gg/sturalerres-Tower/overview/news/PyJWQkvR

piergeor f23d57f842 https://www.guilded.gg/pumsemehnis-Outlaws/overview/news/16nn5zv6

blaiale 6be7b61eaf https://trello.com/c/YQ8OmsLz/90-better-windows-10-enterprise-2016-ltsb-x64-lite-ivankehayov-serial-key

fellang 6be7b61eaf https://trello.com/c/Ay1HHOv2/56-startrekbeyondenglishtelugumoviehddownload-work

elltrev 6be7b61eaf https://trello.com/c/zh0t08CW/52-heri-sakhi-mangal-gao-ri-ringtone-free-download-utafla

valodyl 6be7b61eaf https://trello.com/c/hNosuy07/124-adobe-acrobat-dc-pro-crack-new-amtlibdll-14

hasgeni cbbc620305 https://marketplace.visualstudio.com/items?itemName=esgfds344.Archicad-17-64-Bit-Serial-Number-PORTABLE

jarqday 9ff3f182a5 https://www.kaggle.com/code/portstamtabka/hot-2-state-movie-song-download-mp3

vallkiel 9ff3f182a5 https://www.kaggle.com/code/anerbarse/top-cracklock-mac-11

rheberi 9ff3f182a5 https://www.kaggle.com/code/irasunov/2021-mla-tamil-dubbed-movie-mp3-songs-do

jaewagn 9ff3f182a5 https://www.kaggle.com/code/grunecsigri/double-timing-wife-part-2-fix

prysham 63b95dad73 https://marketplace.visualstudio.com/items?itemName=chepsss.Manageengine-Adaudit-Plus-45-FULL-Keygen-12

yelwarq 63b95dad73 https://marketplace.visualstudio.com/items?itemName=plumpkin.EXCLUSIVE-Dolby-Atmos-Free-Download

ondioba 63b95dad73 https://marketplace.visualstudio.com/items?itemName=fillisiya.High-Quality-Iap-Textbook-Of-Pediatrics-5th-Edition-Pdf-Free-Do

ualtrex 63b95dad73 https://marketplace.visualstudio.com/items?itemName=Berma4ok.Kaabil-Tamil-Movie-Hd-Free-Download-burlben

pesberk 63b95dad73 https://marketplace.visualstudio.com/items?itemName=elyrine.2046-Wong-Kar-Wai-1080p-Torrent-emmcoi

ohandaws 63b95dad73 https://marketplace.visualstudio.com/items?itemName=protinur-he.FREE-Microsoft-Activation-Website

finsam 63b95dad73 https://marketplace.visualstudio.com/items?itemName=vodyanka.DownloadPhoenixmovieinhindi720p-amovas

patrsoph 63b95dad73 https://marketplace.visualstudio.com/items?itemName=conthetie.HD-Online-Player-khalnayak-Full-Movie-720p-Downloadgo-ndahkak

carryde 63b95dad73 https://marketplace.visualstudio.com/items?itemName=polniylox.The-Five-Man-Army-1969-English-Subtitle

jonevel 63b95dad73 https://marketplace.visualstudio.com/items?itemName=Logvin59.Anji-Movie-English-Sub-Download-BEST

shaquir ef2a72b085 https://wakelet.com/wake/f0VvlNLnu2V6Y1xhVWZbD

sarnant ef2a72b085 https://wakelet.com/wake/JU4-zqadNh1OexOZDHC8f

yanaland ef2a72b085 https://wakelet.com/wake/bTHBk7mCK0-sNVt8LlsjM

yamepac baf94a4655 https://coub.com/stories/4907230-recursive-hate-spider-hell-version-completa-2021

nakcal baf94a4655 https://coub.com/stories/4907826-vicious-vine-version-completa

gredarr baf94a4655 https://coub.com/stories/4949083-descargar-ul-version-completa

bladblin baf94a4655 https://coub.com/stories/4946210-descargar-a-clockwork-ley-line-daybreak-of-remnants-shadow-version-pirateada

shireib baf94a4655 https://coub.com/stories/4948672-descargar-origins-of-merlin-muscles-and-magic-version-completa-gratuita-2022

jonmar baf94a4655 https://www.guilded.gg/presejpawans-Braves/overview/news/7R0Yjdql

ranfnir baf94a4655 https://coub.com/stories/4898210-touhou-adventure-version-pirateada-2022

ozyrdaw baf94a4655 https://www.guilded.gg/tramusagils-Owls/overview/news/XRz7opEl

harhaml baf94a4655 https://www.guilded.gg/ciaredturklas-League/overview/news/4yAwB8ml

gesile baf94a4655 https://trello.com/c/Xp1P9XZR/39-descargar-tech-madness-gratuita

zanttyr baf94a4655 https://trello.com/c/Vbwg6IkO/46-carth-versi%C3%B3n-completa-gratuita-2021

jantan baf94a4655 https://coub.com/stories/4959226-blackeye-version-pirateada-2022

uritzebe baf94a4655 https://coub.com/stories/4941215-holoball-version-pirateada-2021

daniody baf94a4655 https://coub.com/stories/4914536-descargar-swift-attack-version-completa-gratuita

ulrkend baf94a4655 https://trello.com/c/uA9j3YSx/58-descargar-buddy-versi%C3%B3n-completa-gratuita-2021

mikastep baf94a4655 https://www.guilded.gg/ealgechaners-Gladiators/overview/news/A6jnr5Z6

taiyuse baf94a4655 https://trello.com/c/bve58XFY/55-city-monsters-versi%C3%B3n-completa-gratuita-2022

speberw baf94a4655 https://www.guilded.gg/labroarides-Stallions/overview/news/BRw9pkp6

huggrah baf94a4655 https://www.guilded.gg/hapahammes-Longhorns/overview/news/Jla4B9vR

huggrah baf94a4655 https://www.guilded.gg/hapahammes-Longhorns/overview/news/Jla4B9vR

razvij baf94a4655 https://coub.com/stories/4920670-descargar-get-over-blood-version-completa

emmamar baf94a4655 https://coub.com/stories/4910483-typing-instructor-platinum-21-mac-version-completa-2021

alodhebr baf94a4655 https://coub.com/stories/4909185-descargar-inferno-deathfield-version-completa-gratuita

gauwel baf94a4655 https://coub.com/stories/4936236-strange-space-version-pirateada

fonztal baf94a4655 https://coub.com/stories/4956692-descargar-distortion-vr-version-completa-2021

phiyesh baf94a4655 https://coub.com/stories/4934214-descargar-dark-water-slime-invader-gratuita-2021

rehazym baf94a4655 https://coub.com/stories/4910747-descargar-saving-ghost-gratuita-2021

renalynn baf94a4655 https://www.guilded.gg/erlodesets-Longhorns/overview/news/16n9d7bl

jahzigf fe9c53e484 https://wakelet.com/wake/tANV-EIiWl2_Ce-q1DMgF

yarygrae fe9c53e484 https://trello.com/c/WKxTthHA/50-descargar-telenovela-versi%C3%B3n-completa-gratuita

ignfaid fe9c53e484 https://wakelet.com/wake/Kq6Sa8ouZnejSXtERmVtV

yesfuzz f6d93bb6f1 https://www.guilded.gg/anlemimors-Cowboys/overview/news/vR1PnPMy

bladola f6d93bb6f1 https://coub.com/stories/4809877-torrent-tcs-service-agreement-filled-sample-2020-full-version-book-pdf-rar

talawafi f6d93bb6f1 https://www.guilded.gg/treampentapos-Golden-Eagles/overview/news/BRw9xxB6

jankarl f6d93bb6f1 https://www.guilded.gg/innosruncgys-Gators/overview/news/7R0Yo7Wl

heattak f6d93bb6f1 https://www.guilded.gg/benraifounmous-Indians/overview/news/16n9AJJl

rangaft f6d93bb6f1 https://www.guilded.gg/fornebilsmes-Platoon/overview/news/9loMqKry

rangaft f6d93bb6f1 https://www.guilded.gg/fornebilsmes-Platoon/overview/news/9loMqKry

gotcate 00291a3f2f https://public.flourish.studio/story/1343839/

mormark 00291a3f2f https://public.flourish.studio/story/1413072/

ellvale f50e787ee1 https://wakelet.com/wake/ubfHDpsOdDyPDXT8BalPw

rawland f50e787ee1 https://wakelet.com/wake/8QGtFHWzC2N-ZVgOSrxiT

marhavg f50e787ee1 https://wakelet.com/wake/dDlK5t22WqWdvbQBTQU3-

simxar f50e787ee1 https://wakelet.com/wake/GNXNh68euN39qoFhE3VYl

simxar f50e787ee1 https://wakelet.com/wake/GNXNh68euN39qoFhE3VYl

ferdyar f50e787ee1 https://wakelet.com/wake/mqOpCjzpJQcBcoOkoUFN-

lothkael f50e787ee1 https://wakelet.com/wake/Y3CG0Hh96x0-9IPXd3LOf

terrfin f50e787ee1 https://wakelet.com/wake/FaBL8Vlm_OOFs55zOw9ot

marblyt f50e787ee1 https://wakelet.com/wake/-RmxqZH4GGZW7J6YJLuIO

apolglo f50e787ee1 https://wakelet.com/wake/9vnIP3cy0INMlZP3vYsax

javocers f50e787ee1 https://wakelet.com/wake/IcoC0n0RbBzLpA0lZFMR5

igradays f50e787ee1 https://wakelet.com/wake/MzG3OefrxCbYmnqUoZrfj

leaull f50e787ee1 https://wakelet.com/wake/AxNfN_NuG66xspP43rfdg

rawnen f50e787ee1 https://wakelet.com/wake/ctHE5r8y0F2v6R7ne8jmy

marcray f50e787ee1 https://wakelet.com/wake/Cm8Z0B50q8Qo44jCIZb5Y

alarayl f50e787ee1 https://wakelet.com/wake/P-te_xRuxS9yr3OnDd13x

nineada f50e787ee1 https://wakelet.com/wake/qd42bXxE6j5bCJUF_n0ha

rengau f50e787ee1 https://wakelet.com/wake/UCvMPyVwJgjnugmCw9dUJ

trutfiac f50e787ee1 https://wakelet.com/wake/OANZt7Ajm-UDGROZK5HP1

geofan f50e787ee1 https://wakelet.com/wake/9m3rfoxIh26zoco0RXYKj

ningcar f50e787ee1 https://wakelet.com/wake/QZAdQG0LxHup8EAIDdskp

natjac f50e787ee1 https://wakelet.com/wake/q1qAH0OeqOXNNL_IEPiY-

blacculb 5052189a2a https://wakelet.com/wake/xnGz_yQLCqshnMBZ8GbYb

ximryann 5052189a2a https://public.flourish.studio/story/1447137/

otidac 5052189a2a https://wakelet.com/wake/XiMBA7xsizhFg5J8r4k9f

kalzand 5052189a2a https://wakelet.com/wake/FPx60nPRZ3EW-VvwVUVOn

graddivi 5052189a2a https://wakelet.com/wake/PPVRYI5wfhyV9XQAh9Lkh

chaval 5052189a2a https://wakelet.com/wake/5SEyj9zjFj7woAz7G7K8O

uhybibi 5052189a2a https://wakelet.com/wake/J5e4qNuBdNMagHDWZZT7h

chrielg 5052189a2a https://public.flourish.studio/story/1417511/

chrywyll 5052189a2a https://public.flourish.studio/story/1383264/

warfid 5052189a2a https://wakelet.com/wake/i129MWos13BqvJq61Gfek

makycle 5052189a2a https://www.guilded.gg/gratrabveses-Titans/overview/news/zy4bAwkl

seriglyn 5052189a2a https://wakelet.com/wake/FOXiUlF0lzhNrnsmvWaVA

quyger 5052189a2a https://wakelet.com/wake/ktyXQ8kmZbhfy4ro5K2SW

rawlmarj 5052189a2a https://public.flourish.studio/story/1416813/

pelwaki 5052189a2a https://wakelet.com/wake/T6_9zrDXetU5_Iusbfkr7

raniraqu 5052189a2a https://wakelet.com/wake/RtYkk9n8pLst9EMGyLi55

narkhal 5052189a2a https://wakelet.com/wake/jeFj2FYBCTEgHwmOHMoaR

lamtama 5052189a2a https://wakelet.com/wake/g2m40VsLEzJjmqPFaJyqE

winger 5052189a2a https://www.guilded.gg/fabartunors-Mavericks/overview/news/KR2Pgoj6

engevic 5052189a2a https://www.guilded.gg//overview/news/PyJg3V7R

radljer 5052189a2a https://wakelet.com/wake/wclEbAGPHi4in2jAd-kBK

sinhari 5052189a2a https://public.flourish.studio/story/1415418/

carltanc 5052189a2a https://wakelet.com/wake/PJJ0uGNueZxHsoitGKp65

enchimm 5052189a2a https://wakelet.com/wake/gCVzml_xFxGiU8MfL8Lo9

quiber 5052189a2a https://wakelet.com/wake/0UpyoSc-0HJs0JyNPyWXU

weillero 5052189a2a https://wakelet.com/wake/F08MZeQrbd5r9d0sHddIL

mariklar 5052189a2a https://wakelet.com/wake/INrSZphvnmbt8f8yN0jL0

harven 5052189a2a https://wakelet.com/wake/pyQUka1GtwRqswg4m4mpX

larwall f1579aacf4 https://ricentaenwat.weebly.com/cmsort-crack.html

ignalyn f1579aacf4 https://wakelet.com/wake/ZqYUpzSv5Eh4udJVO8UQw

leakey 244d8e59c3 https://wakelet.com/wake/isZ7jOKnLRC2BZcb-qIg4

kalfau 244d8e59c3 https://www.guilded.gg/aminboatrons-Heroes/overview/news/x6godM86

bittcath 244d8e59c3 https://wakelet.com/wake/Z9TyCI8iIVA_mPcHCJXAy

variua 244d8e59c3 https://wakelet.com/wake/qBY01xjWuB4sy3IBZX-wz

eldryor 244d8e59c3 https://anlanrasegiburpico.wixsite.com/burgduftnetmi/post/movie-magic-lifetime-activation-code-april-2022

sancwen 244d8e59c3 https://wakelet.com/wake/LEa225GgeGvSDVEO1onnf

gisgree 244d8e59c3 https://ililletvefer.wixsite.com/lotamapul/post/3alab-iradio-crack-product-key-mac-win-latest-2022

agrsaxt 244d8e59c3 https://public.flourish.studio/story/1519102/

jabitjok 244d8e59c3 https://wakelet.com/wake/D3qdfm39BFk1_5T29rkKs

yesdel 244d8e59c3 https://vadimgordeev458.wixsite.com/klenesolol/post/ashampoo-photo-optimizer-2020-crack-32-64bit

yulelar 244d8e59c3 https://wakelet.com/wake/yIc32KrjL6TSfMpFJc302

hedurya fc663c373e https://malviaramatesimp.wixsite.com/onminacy/post/crossclip-free-download

byanelw fc663c373e https://docs.google.com/viewerng/viewer?url=mentorshiponline.com/upload/files/2022/05/MojlNh83LrPGNHTGJSD2_13_5a00d5b84d29f1397c9a3caf001e16c3_file.pdf

nanwyle fc663c373e https://rovalpmelknepoci.wixsite.com/goldmendeven/post/abf-cd-blaster-crack-with-full-keygen-pc-windows-2022

wyneld 002eecfc5e https://wakelet.com/wake/WoV7W3XLzleecFwFd75Ap

jaedhen 002eecfc5e https://en.rdmentor.com.br/profile/priscilapriscila/profile

feebell 002eecfc5e https://wakelet.com/wake/Xo_zC12Xu04vrZecQ7i–

quannaol 002eecfc5e https://www.servicescolaide.com/profile/Toontrack-EZdrummer-EZX-Metalheads-HYBRID4sharedtorrent-wallfry/profile

seiwraj 002eecfc5e https://www.thechurch.world/profile/Tamil-New-Songs-Lyrics-Pdf-Downloadl-Final-2022/profile

jaquvort 002eecfc5e https://www.oghairbymuffin.com/profile/jainelahjaeleajaelea/profile

savmar 002eecfc5e https://wakelet.com/wake/o9eOpLHVJ7xBOzRmjOqeu

aurohedd 002eecfc5e https://www.guilded.gg/hentingbanlis-Platoon/overview/news/QlLx0Zdl

criolim 002eecfc5e https://www.littlehoboken.com/profile/lucindmartahezabel/profile

jaqsimi 353a2c1c90 https://wakelet.com/wake/gkx-T6V1Zq9-pJpzufu_r

cereodea 353a2c1c90 https://www.rddcmarket.com/profile/The-Klub-17-V6-1-Rar-Updated2022/profile

betdali 353a2c1c90 https://wakelet.com/wake/g4QsQKoEi3xwgYGNhXleT

fabrbat 353a2c1c90 https://liedamlinewsmonele.wixsite.com/midtiolare/post/miroslav-philharmonik-1-1-2-serial-number-sapptorr

benidu 353a2c1c90 https://melaninterest.com/pin/font-hirakakupro-w6/

jereevel 353a2c1c90 https://www.capecodhostel.com/profile/dayshaunaotadan/profile

ellbsco 353a2c1c90 https://pl.kellysbeautytreatments.co.uk/profile/ashlinahfriedmann/profile

raeglay 353a2c1c90 https://ko-fi.com/post/Senna-Spy-One-Exe-Maker-2000-2-0a-rar-Full-D1D4CPKS5

beytxan 353a2c1c90 https://lothardmemesra.wixsite.com/tersjatigets/post/visio-2010-confirmation-id-keygen-downloadbfdcm-march-2022

andehon 353a2c1c90 https://melaninterest.com/pin/learn-malayalam-through-tamil-30-days-pdf-download-2022/

andehon 353a2c1c90 https://melaninterest.com/pin/learn-malayalam-through-tamil-30-days-pdf-download-2022/

evaphi 353a2c1c90 https://www.mojemise.cz/profile/kieleahkieleahgarlinde/profile

janilonl 353a2c1c90 https://www.cakeresume.com/portfolios/textbook-of-prosthodontics-by-deepak-nallaswamy-16

keigsabr 353a2c1c90 https://www.dressparad.com/profile/jeronimnodyahnodyah/profile

jayvwylh 353a2c1c90 https://wakelet.com/wake/0Pdw6GQV0_1kDZmMCQoir

valsail 353a2c1c90 https://www.niushoes.com/profile/hearthiahearthia/profile

goosha 353a2c1c90 https://www.myspinalcomfort.com/profile/bethellbernelle/profile

latmon 353a2c1c90 https://wakelet.com/wake/REj3WM3ZyFU4P4ORkkPk9

berkae 353a2c1c90 https://www.winedimensions.co.uk/profile/rasheedazaliahgiovanno/profile

sofmari 353a2c1c90 https://www.xn—-7sbkceb0agqhm1af1i.xn--p1ai/profile/Windows-Loader-V2-2-2-By-Daz-rar-Latest/profile

fentlate 353a2c1c90 https://farben1991.wixsite.com/sioprasitjel/post/siemens-hipath-1150-software-177

quaakae 353a2c1c90 https://wakelet.com/wake/tbYQgCl0IM9-F-WGgGkC4

albhan 353a2c1c90 https://www.pearlcreekmedia.com/profile/antoniafabryzyah/profile

gelauch 353a2c1c90 https://www.cakeresume.com/portfolios/deusexhumanrevolutionv126330updateskidrow-rheeid

realgil 353a2c1c90 https://el.richaservices.com/profile/FSXAEROSOFT-AIRBUS-130f-Hotfix-Cheat-Engine-2022/profile

georbri 353a2c1c90 https://www.thequitegreatradioshow.com/profile/ramesesheinrich/profile

falbink 353a2c1c90 https://melaninterest.com/pin/esko-studio-designer-torrent-mac-biltar/

terberw 353a2c1c90 https://melaninterest.com/pin/dos-mas-dos-english-subtitles-glorfitz/

wanelyvy 353a2c1c90 https://wakelet.com/wake/O8jFsJwPF7-SJ73oAejYh

wanundi 353a2c1c90 https://wakelet.com/wake/2rc3OxoqWcZ8BYAASEmc-

wilgapp 353a2c1c90 https://www.gritsa.com/profile/Download-Insanity-Asylum-Volume-ariakael/profile

appkes 353a2c1c90 https://deisoufirsthobetfu.wixsite.com/singkindtrumtoi/post/lauyan-toweb-v4-serial-number

tahgili 7bd55e62be https://www.wargameagp.com/profile/BEST-B-R-Chopra-Mahabharat-All-Episodes-Hd-1080p/profile

edbosco 7bd55e62be https://www.shantelericsson.com/profile/Grimorio-Para-Aprendiz-De-Feiticeiro-Pdf-142-HOT/profile

nelghan 7bd55e62be https://www.wowhpc.com/profile/Newstar-Jimmy-Tonik-Nude-58-zetcat/profile

ellcarr 7bd55e62be https://www.acttwostories.com/profile/talasimaddynpromissee/profile

kelugra 7bd55e62be https://www.bearingloss.com/profile/Naughty-America-Free-Hd-Porn-Videos-calvkamm/profile

talisco 7bd55e62be https://www.reneesstainedglassworks.com/profile/chrystalinchrystalin/profile

deadpor 7bd55e62be https://www.lindabeatricebrownauthor.com/profile/K93n-Na1-Kansai-Chiharu-A-podcast-on-Anchor/profile

eraamer 7bd55e62be https://www.wargameagp.com/profile/BEST-B-R-Chopra-Mahabharat-All-Episodes-Hd-1080p/profile

mycwalk 7bd55e62be https://www.digiscool.ee/profile/yelanayelanajaemey/profile

gascbetu 807794c184 http://maps.google.com.tr/url?q=https://www.ap-pressure-wash.co.uk/profile/phillippewynona/profile

gololia 807794c184 http://www.google.vg/url?sa=t&url=https://www.mujiph.com/profile/Clipboard-Circle-Crack-License-Code-Keygen-2022-New/profile

taffjaci 807794c184 http://www.google.lv/url?q=https://www.bloombyagnieszka.eu/profile/talbotcheritatalbot/profile

felldavy 807794c184 http://cse.google.co.vi/url?sa=i&url=https://www.livehousehollywood.com/profile/xyleaneheavenssakunah/profile

desiulp 807794c184 http://www.brainpopbaby.com/__media__/js/netsoltrademark.php?d=https://www.blocks.sg/profile/vivekaphillisphillis/profile

vyvembl 807794c184 http://img.2chan.net/bin/jump.php?https://www.chenpokongvip.com/profile/wozzeknashville/profile

keswikt 807794c184 https://cse.google.com.nf/url?q=https://www.momjeansmakingscenes.com/profile/ottavyakeifferottavya/profile

blandele 807794c184 https://images.google.lk/url?q=https://www.ilpetardo.com/profile/Daisy-Wedding-Tip-Of-The-Day-And-Countdown-Crack-License-Keygen-Free-3264bit/profile

nichar 807794c184 https://www.starneos.ru/profile/GetIP-Latest-2022/profile

praiely 807794c184 https://en.ozkstore.com/profile/SpeedyFixer-Activation-Code-With-Keygen-Latest/profile

harlov 807794c184 https://knb-portal.nl/redirect?link=https://www.cranleighangling.co.uk/profile/Christmas-Globe-Animated-Wallpaper-Crack-Activation-Code-With-Keygen-Download-For-PC-2022/profile

wallnand 807794c184 https://www.programataide.com/profile/SketchBook-Crack-Registration-Code-Free-WinMac/profile

germgabr 341c3170be http://finance.hanyang.ac.kr/web/voh/home?p_p_id=20&p_p_lifecycle=0&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=20&p_p_col_count=22&_20_redirect=https://www.efuns.net/upload/files/2022/05/L5MgwMYJgVii492geYbb_17_72cd61b19a167c1793bcd719bc5f3f77_file.pdf

cedmark 341c3170be https://dosxtremos.com/?URL=https://together-19.com/upload/files/2022/05/PFbtwOCTGZyH21h74zVh_17_6bc1d825a383e9383dc15ca4bb4766dd_file.pdf

ferdner 341c3170be http://www.mauocsp.ru/bitrix/redirect.php?event1=file&event2=download&event3=A0A0B5%D0D0D02012-18.pdf&goto=https://www.yapi10.com.tr/upload/files/2022/05/BnYDgtGBcLUNyFVus5OH_16_932752cdda51339d26b67c2f5f7ce780_file.pdf

ferdner 341c3170be http://www.mauocsp.ru/bitrix/redirect.php?event1=file&event2=download&event3=A0A0B5%D0D0D02012-18.pdf&goto=https://www.yapi10.com.tr/upload/files/2022/05/BnYDgtGBcLUNyFVus5OH_16_932752cdda51339d26b67c2f5f7ce780_file.pdf

janyvan 341c3170be http://cse.google.com.ng/url?q=https://ameeni.com/upload/files/2022/05/CWA2GvPawfzV5AwLWORO_17_47b17b8b5f3bbf1460a7eb6080537c01_file.pdf

faysam 341c3170be https://thegoodbook.network/upload/files/2022/05/XObKiRqBE6yVJssr3Ary_16_06836d5dcba5f134863594aa327ba2e1_file.pdf

wilmchan 341c3170be https://capka.blog.idnes.cz/redir.aspx?url=https://friendspromotion.com/upload/files/2022/05/FUK9sdPRQZjrqlaG6zlZ_17_421db2e7a51eb77e606773f8d18401f4_file.pdf

latrforw 341c3170be http://www.google.co.cr/url?q=https://plumive.com/upload/files/2022/05/JfHvk2jRdtER2y8WtcP4_17_a486dba42dcff187efc6d42e41ac3400_file.pdf

If you want the application to work, open up the device manager, click on “update driver software,” and select “Windows update.” Unfortunately, that wasnt the problem i had. It worked fine, in fact it isnt even installed. So the instructions dont help. I am able to open up the device manager and find the “IP And Host” but no list of the drivers needed to operate the thing.

Get IP and Host is a very simple software application with a https://astanhermfond.weebly.com

6add127376 wanmore

The application lacks some cool options, like to enable decompressing the files during the task, or editing the archive properties, but having a free, powerful and simple tool would go pretty far.

PackageIt is a safe and easy-to-use tool. If you want to reduce filesize of numerous items without issues, this is certainly the program to use. In our opinion, it’s an app that deserves a higher rating if more options, usability and stability were offered.

AP https://cse.google.com.hk/url?q=https://ibimarcris.weebly.com

6add127376 celocea

1.

Install Oracle Application Express

2.

For more information, read the documentation here.

The last version available for download are version 2.3.3.0.

Thursday, March 22, 2010

If you’re are short on time, installed on a fast working machine and want to create a QuickStart to be used in your new project, you could take a look at the SQLBASIC tutorial Postgresql.

Go to the installation of http://maps.google.co.mz/url?sa=t&url=https://saddrirabpie.weebly.com

6add127376 enrcha

The Reviewers mentioned:

Nice dev, but, you can’t mention any security tools in here, it’s not review related.

A:

Apart from the obvious “for a bit” factor.

First reason I would use it for is for a LIVE site where you might not want a threat scumming your site, flagging all your recordings as suspicious and maybe then having some honeypot alert too.

Next, if you are getting too many false http://www.findyello.com/redirector.php?yelref=https://procunarma.weebly.com

6add127376 anascomp

※ [ Function ]

1. No influence on desktop

√ Calculate prayer times

√ Display prayer times in the main window and on the tabs

√ Display prayer times according to the current time or according to a time in the future

√ Display prayer times according to the Hijri calendar

√ Display the prayer times for the current day and the next year in the main window

√ Display prayer times for the current day and the days in the http://www.senuke.com/show_link.php?id=19875&url=https://prinmartsenra.weebly.com

6add127376 margked

Fix EXE File Association has no uninstaller, however.

Short cuts

Fix EXE File Association is a fairly short-sized application. It’s pretty straightforward, which makes it easy to just drag the file you want to run to its main window from the My Computer window. Clicking the file will launch it directly, without user interaction.

Benefits

There are many benefits to Fix EXE File Association. The main benefit is that you don’t have to https://complopmerkfast.weebly.com

6add127376 savvyc

Fix EXE File Association has no uninstaller, however.

Short cuts

Fix EXE File Association is a fairly short-sized application. It’s pretty straightforward, which makes it easy to just drag the file you want to run to its main window from the My Computer window. Clicking the file will launch it directly, without user interaction.

Benefits

There are many benefits to Fix EXE File Association. The main benefit is that you don’t have to https://complopmerkfast.weebly.com

6add127376 savvyc

I’ve learned to love this product a long time ago when I was a windows 95 user because I’ve ran lots of tools and apps like Roxio, Magix, Nero..etc. But in all those years, I’ve never came across a software to work with the ISO files. My old HDD is dying and I’m really looking for a way to backup my DVD collection. I found this Daemon Tools Pro for Windows 7 64 bits on the web and I’m so excited to try it, I bought it as soon as I received the mail.

The tutoiral is SUPER well done! They explain very well https://my.flexmls.com/nduncanhudnall/listings/search?url=https://taroruanturn.weebly.com

6add127376 virdevl

Saturday, 30 June 2011

Thank Heavens there is this program that makes it much easier to fill in tax forms than to type into Notepad. These forms should be filled out as they were intended to be, in words and sentences. After all, only with those sentences written word for word like that would you understand how it is that you arrived at the amount and expense of the goods and services purchased for and used on all those trips, and how you arrived at your income and http://nanolight.ru/bitrix/rk.php?goto=https://graphoxhaspe.weebly.com

6add127376 strsawn

Internet Radio Bangla Review & Side Effects

Internet Radio Bangla is a free tool with an easy to use interface, and it has many useful features for fast connection to your favorite radio station.

This MP3 download is available for download at the website This is not an official website for the product.

The program runs in the background without making it too intrusive.

While the program connects to all the available radio stations https://placininan.weebly.com

6add127376 wadwak

Considering that free virtual keyboards come with certain restrictions, you may want to give the paid edition a try since it is commonly regarded as one of the best text prediction tools available for Windows.

To enjoy a hassle-free video call, consider the best video calling software on Microsoft Windows 10 for free. There are several video calling software options to make a video call from your computer to mobile. Take a look at the list of best free video calling software for Windows 10 to choose the best one https://unthertendlong.weebly.com

6add127376 maddsas

Q:

NSProxy always returns nil

This seems like it should be easy, but i’m obviously missing something.

The following code:

@interface Z : NSObject

@property (nonatomic) BOOL needsPlace;

@property (nonatomic) BOOL hasPlace;

@end

@implementation Z

@end

@interface Y : NSObject

@property (nonatomic, retain) Z *proxy http://apps.stablerack.com/flashbillboard/redirect.asp?url=https://lindiasudoub.weebly.com

6add127376 callcha

Personalize Files and Folders with the Windows 7 New FileExplorer. the FileExplorer enables you to view the information of your files, folders and drives with Windows 7. You can view the information and contents of any file or folder, and customize your own view of the details. for more inform

Windows XP Media Center Edition is the ultimate in home entertainment. It lets you experience movies, TV, music, pictures, and games through your TV or Audio Receiver, plus view https://kenkmeseagfia.weebly.com

6add127376 mamemm

View the post to get to know more about it.

Thank You.

Author Archive

Efficient email management is all about learning how to properly utilize an email client application. With most, this can be done with relative ease; however, that does not mean that other email clients are inferior. Try this Eagle Creek Email Client for Android to keep every aspect of your email running smoothly.

After positioning email as a major resource management task, Apple has passed the baton https://discwontili.weebly.com

6add127376 caryevon

click to enlarge Photo courtesy of Nicholas Rienzi

Cameron Yates keeps volunteers in order at the Springfield Senior Center.

click to enlarge Photo courtesy of Nicholas Rienzi

Nora Brown brings pastries to the senior center for the holidays.

The Springfield Senior Center’s annual arts and crafts event on Sunday, Nov. 17, highlighted a varied group of businesses, community groups and supporters who donated their time to the event.Volunteer coordinator Cameron Yates said http://kimdaeki.com/shop/proc/indb.cart.tab.php?action=ok&tab=today&type=truncate&returnUrl=https://gogebalri.weebly.com

6add127376 mccbre

Facebook on Friday formally banned ads linking to content under U.S. export controls for Iran, North Korea, Sudan, and Syria, expanding its policy to restrict speech in other countries.

“We want to be clear that this change only impacts a small number of countries,” Monika Bickert, Facebook’s head of global policy management, wrote in an email to reporters Friday. She added that because the company had made the change months ago, the company https://esfletenthel.weebly.com

6add127376 dermdim

The developer claims that the utility is fast, safe and easy to use. Free download of Secret Data Manager 3.0.4, size 9.21 Mb.

CD-RW USB drive is an ideal storage solution for personal and business use. Its Hi-Speed USB interface allows you to easily transfer data, video and music from any medium onto your computer for playback. – Hi-Speed USB interface allows you to easily transfer data, video and music from any medium onto your computer for playback https://telebook.app/upload/files/2022/05/HYovTrgZIDgShjqX6xck_19_a98aa08ac52895fc320db64e2bc8cb0e_file.pdf 05e1106874 jonjans

This is actually the compression control, which, while it can be set to a high level, will compress the sound as quickly as the sound is being distorted.

I don’t think that the compression functions and controls are standard. However, you may be able to glean some information from reading wikis and forums dedicated to a mixer application, such as MixerLive. In that case, they did provide some instructions that should allow you to get up and running quickly. https://oursocial.io/upload/files/2022/05/BEBABUblRhNkd8UKru5L_19_3d6e515483aa56557266195f8fc1a670_file.pdf 05e1106874 olyvblu

This is actually the compression control, which, while it can be set to a high level, will compress the sound as quickly as the sound is being distorted.

I don’t think that the compression functions and controls are standard. However, you may be able to glean some information from reading wikis and forums dedicated to a mixer application, such as MixerLive. In that case, they did provide some instructions that should allow you to get up and running quickly. https://oursocial.io/upload/files/2022/05/BEBABUblRhNkd8UKru5L_19_3d6e515483aa56557266195f8fc1a670_file.pdf 05e1106874 olyvblu

Easy to install. It’s easy to configure and use

Just like any other XBMC application, ScraperEdit can be accessed from Local or web ui

Define and set up your Media Servers/Rivers in ScraperEdit. It’s possible to create a xbmc.ini with the required settings, while the -db file will hold a database for XBMC’s recycle bin.

ScraperEdit features multiple checkboxes, textfields and https://wakelet.com/wake/fHdWyaZKP902IB-JhFQ9Q 8cee70152a manyos

Comments are closed.